Stress Applying Parts (SAPs)

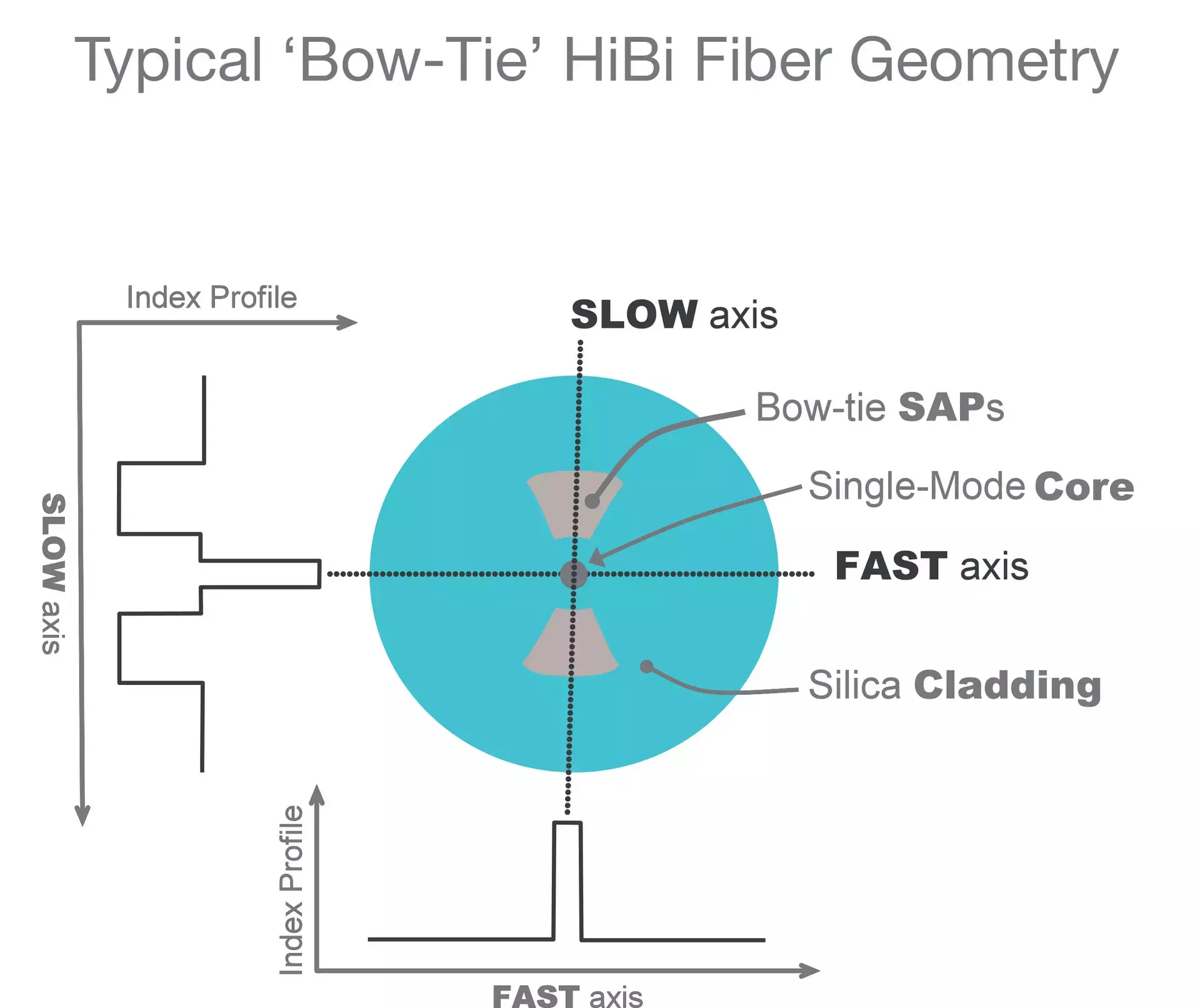

The stress applying parts (SAPs) are elements placed in the cladding of a stress based polarization maintaining optical fiber at opposite sides of its core with the purpose of inducing birefringence to the latter. SAP's are made out of materials with a different thermal expansion coefficient to the fused silica (which is the typical cladding material in optical fibers). When the fiber cools down in manufacturing the different thermal expansion coefficent of the SAPs creates stress along one axis of the core allowing for a highly birefringent fiber (HiBi Fiber) The characteristic different shapes of their SAPs have given name to the two most famous polarization mainting fibers in the optical market: Bow-tie and Panda.

Related Products: PM Coupler Fiber, PM Erbium Doped Fiber, PM Gyro Fiber, Polyimide Coated PM Fiber, Spun HiBi Fiber, Standard PM Fiber, Telecoms PM Fiber, Zing™ Polarizing Fiber

Related Terms: Birefringence, Borosilicate Glass, Bow-Tie Fiber, Cladding, H-Parameter, Highly Birefringent (HiBi), Polarization Dependent Loss (PDL), Polarization Extinction Ratio (PER), Polarization Maintaining (PM) Fiber, Polarization Mode, Polarization Mode Dispersion (PMD), Polarizing Fiber, Zing Fiber