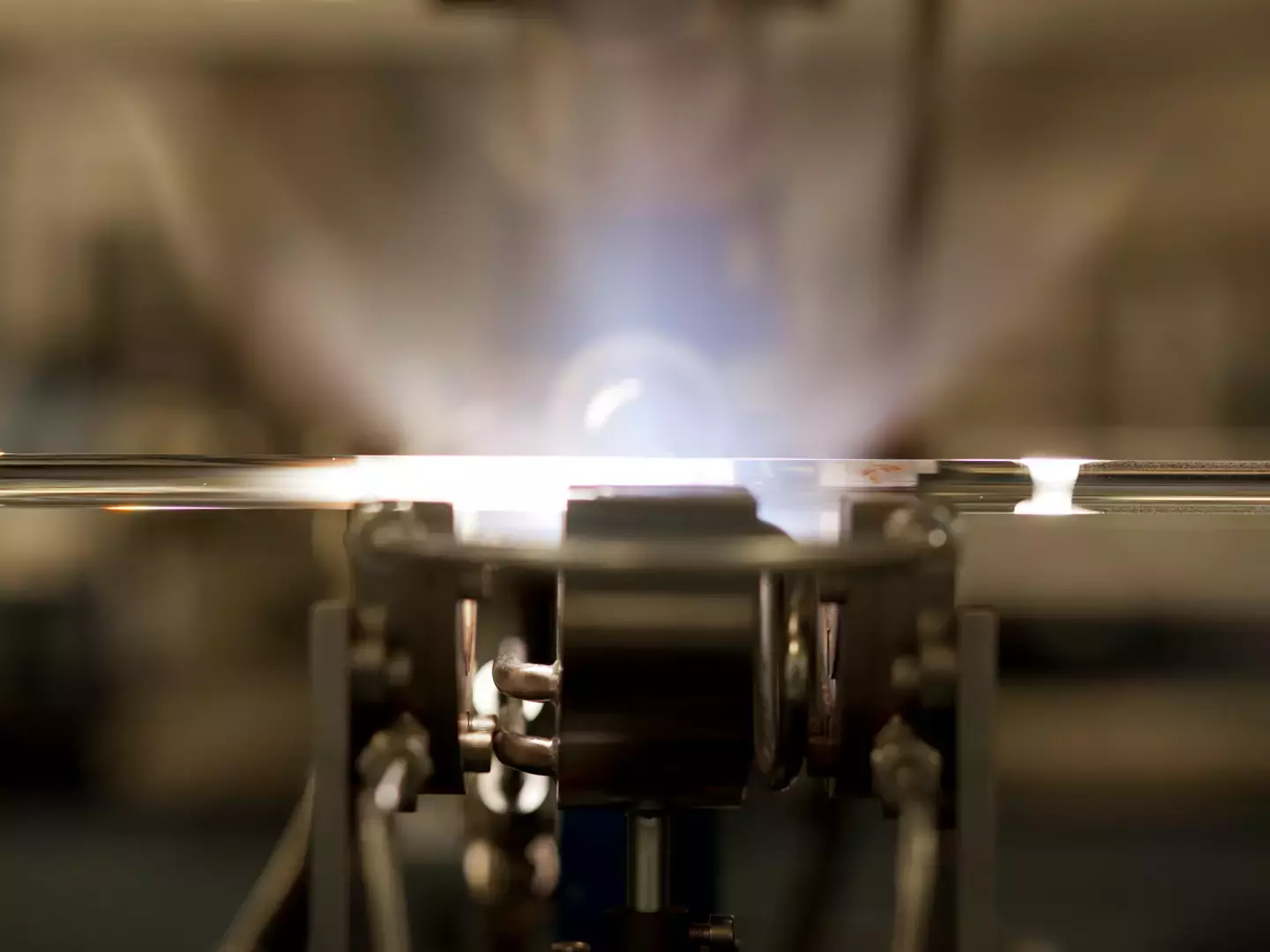

Spun HiBi Fiber

Bow-Tie spun fiber for Faraday effect current sensors

- Circularly birefringent

- Supported by full range of complementary fibers

- Higher Verdet constant at 1310nm than at 1550nm

Typical Applications:

- Current sensors

- Current transformers

- Faraday effect sensors

The spun HiBi fiber allows highly sensitive and accurate current sensing over a wide range of environmental conditions including temperature variation and vibration, making it suitable for current transformers deployed outdoors in real-life applications. When used in conjunction with Fibercore’s PM fiber for delay lines and ZING™ for depolarizers, world-class current sensors can be achieved.

Comparison

| | SHB1250 (7.3/80)–2.5mm | SHB1250 (7.3/80) | SHB1250 (7.3/125) | SHB1500 (8.9/125) |

|---|---|---|---|---|

| Operating Wavelength (nm) | 1260-1510 | 1260-1510 | 1260-1510 | 1510-1650 |

| Cut-Off Wavelength (nm) | 1100-1250 | 1100-1250 | 1100-1250 | 1360-1500 |

| Numerical Aperture | 0.14-0.17 | 0.14-0.17 | 0.14-0.17 | 0.13-0.16 |

| Mode Field Diameter (μm) | 6.2-7.8 @1310nm | 6.2-7.8 @1310nm | 6.2-7.8 @1310nm | 7.9-9.9 @1550nm |

| Attenuation (dB/km) | ≤5 @1310nm | ≤5 @1310nm | ≤5 @1310nm | ≤3 @1550nm |

| Circular Beat-Length (mm) | 63-135 @1310nm | 63-110 @1310nm | 63-110 @1310nm | 86-160 @1550nm |

| Spin Pitch (mm) Nominal | 2.5 | 4.0 | 4.0 | 4.0 |

| Proof Test (%) | 1 (100 kpsi) | 1 (100 kpsi) | 1 (100 kpsi) | 1 (100 kpsi) |

| Cladding Diameter (μm) | 80 ± 1.5 | 80 ± 1.5 | 125 ± 2 | 125 ± 2 |

| Core Cladding Concentricity (μm) | ≤1.0 | ≤1.0 | ≤1.0 | ≤1.0 |

| Coating Diameter (μm) | 165 ± 5 | 165 ± 5 | 245 ± 7 | 245 ± 7 |

| Coating Type | Dual Layer Acrylate | Dual Layer Acrylate | Dual Layer Acrylate | Dual Layer Acrylate |

| Operating Temperature (ºC) | -55 to +85 | -55 to +85 | -55 to +85 | -55 to +85 |

Specifications

Product Variants Explained

| SHB1250(7.3/80) - 2.5mm | Spun HiBi Fiber with an 80µm cladding diameter, designed for use around 1310nm and with a 2.5mm spin pitch. |

| SHB1250(7.3/80) | Spun HiBi Fiber with an 80µm cladding diameter, designed for use around 1310nm |

| SHB1250(7.3/125) | Spun HiBi Fiber with an 125µm cladding diameter, designed for use around 1310nm |

| SHB1500(8.9/125) | Spun HiBi Fiber with an 125µm cladding diameter, designed for use around 1500nm |

Product Specifications

| Operating Wavelength (nm) | 1260 - 1510 |

|---|---|

| Cut-Off Wavelength (nm) | 1100 - 1250 |

| Numerical Aperture | 0.14 - 0.17 |

| Mode Field Diameter (μm) | 6.2 - 7.8 @1310nm |

| Attenuation (dB/km) | ≤5 @1310nm |

| Circular Beat-Length (mm) | 63 - 135 @1310nm |

| Spin Pitch (mm) Nominal | 2.5 |

| Proof Test (%) | 1 (100 kpsi) |

| Cladding Diameter (μm) | 80 ± 1.5 |

| Core Cladding Concentricity (μm) | ≤1.0 |

| Coating Diameter (μm) | 165 ± 5 |

| Coating Type | Dual Layer Acrylate |

| Operating Temperature (°C) | -55 to +85 |

Resources

Technical Bulletins

File

spun_fiber_md22.8.pdf