Optical space communication is an exciting and growing region of the communication industry. The ability to utilize optical techniques in space allows high speed and highly secure communication across the globe.

By moving the amplifiers into the space environment, signal transmission time can be reduced in comparison to an all fiber optic transmission line. Many of the optical power and dispersion limitations can be overcome by transmission through a vacuum rather than through a silica fiber. The improved security feature is realized through the requirement to have direct line-of-sight between the optical transmitter and receiver. To be able to intercept the signal, a satellite would physically need to position itself between the transmitter and receiver, creating an interruption of the signal continuity, which can be detected.

Due to the extreme distance between satellites and the difficulty in achieving the perfect collimation of a beam, the beam size will expand by the time it reaches the next satellite. This will cause a drop in the signal power level and will, therefore, need amplification before reemission. An elegant way of amplifying and remitting the signal in a different direction is to use relatively short amounts of optical fiber, which can be used as both a directional router and an amplifier. To address the need for space-grade optical amplifiers, Fibercore has developed Erbium Doped Fiber AstroGainTM.

AstroGain™

Fibercore has developed AstroGainTM fiber optimized for multichannel amplifiers used in optical satellite communications and control. The fiber has been designed to take full advantage of the photo-annealing effect that results from pumping in the 980nm region. The proprietary

trivalent structure of the core matrix allows optimum recovery following radiation damage to the fiber, whilst also providing a market-leading Erbium Doped Fiber Amplifier (EDFA) efficiency. Direct measurements have been taken of amplifier efficiency in a multichannel assembly, which shows an effective photo-annealing recovery of up to 100% of the radiation-induced attenuation through excitation of point defects.

The base material of a fiber is commonly silica with a doped core to raise its index for guidance purposes. Erbium Doped Fibers (EDF) have additional trivalent dopants, which introduce more point defects intrinsically. Previous work has demonstrated that, in particular, it is a ratio of Aluminum to Erbium in the dopant that can cause more Radiation-Induced Attenuation (RIA), whilst it has previously been reported that a full recovery from radiation damage to optical fibers can be found from pumping at both 980nm and 532nm. This is not an ideal solution for space applications, as the use of multiple pumps requires more mass, power, and adds another layer of complexity in reliability testing.

Dose Rate

When dealing with technological applications in space, the radiation environment must always be a consideration. The Sun, which is the principal source of radiation, emits various forms of hazardous radiation through solar wind and Solar Particle Events (SPE). In addition to SPE, there are Galactic Cosmic Rays (GCR), energetic charged particles from Deep Space. These are less apparent because the solar activity deflects the GCR. Coronal Mass Ejection (CME) is seen alongside solar flares and release a much greater flux of SPE, these have been known to cause mission failure.

There are also regions of trapped electrons and protons within the inner magnetosphere, known as the Van Allen belts. These are between 60 and 6000 miles altitude for the inner belt and between 8,400 to 36,000miles for the outer belt. Due to their nature as regions of trapped radiation, it can be particularly harmful to have the satellites orbiting within the radii of the Van Allen belts without appropriate shielding. Their radial positions can also vary with solar activity, so specific orbital tracks must be considered.

Different elevation orbits have different associated radiation dose rates, resulting in different total doses depending upon the mission lifetime. A higher total dose is more harmful to both humans and equipment. It is also believed that a higher dose rate can have a more detrimental effect, such that even if exposed to the same total dose, a higher dose rate test will be more damaging than a long slow exposure in space. In a geostationary orbit for 20 years, the expected total dose is 137Gy from behind 10mm thick aluminum shielding. In Low Earth Orbit (LEO) the dose is less than half of this value.

Both SPE and GCR lead to distortions in the lattice of a material and have specific effects on different types of materials, which can lead to defect creation in the fiber lattice structure. Radiation-induced defects will absorb light, resulting in RIA. In order to keep the fiber as radiation tolerant as possible, it is therefore important to keep as perfect a lattice structure as possible.

Subscribe for Insights!

Register to receive Fibercore's latest key updates, events and relevant industry news

straight to your inbox!

Photo-Annealing

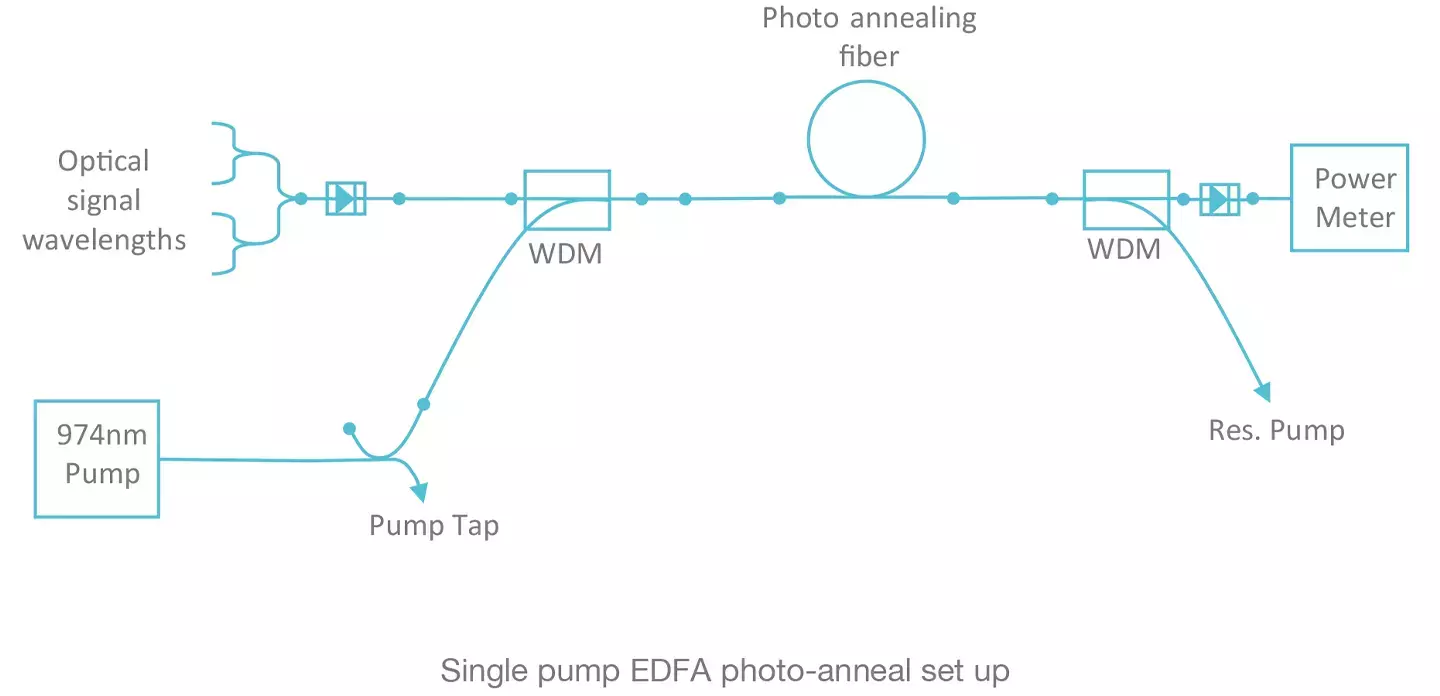

Photo-annealing was performed after this period using a pump at 974nm with 175mW of optical signal wavelengths at 1536.61nm, 1541.35nm, 1550.92nm, and 1552.52nm. As can be seen in Figure 1, the experimental set-up simulates a standard EDFA configuration without any additional pump sources or components.

Figure 1. Single pump EDFA photo-anneal set-up

The method of fully irradiating the fiber at a high dose rate for a short amount of time before commencing photo-annealing is not identical treatment to simultaneously irradiating the fiber and photo-annealing, as would occur under continuous use in Earth orbit. Instead, giving the total dosage in a short amount of time and then annealing the fiber simulates a worst case scenario, since all the damage requires annealing at the outset. A higher dose rate in a short period has been shown to produce more damage than the equivalent lower dose rate for a longer period.

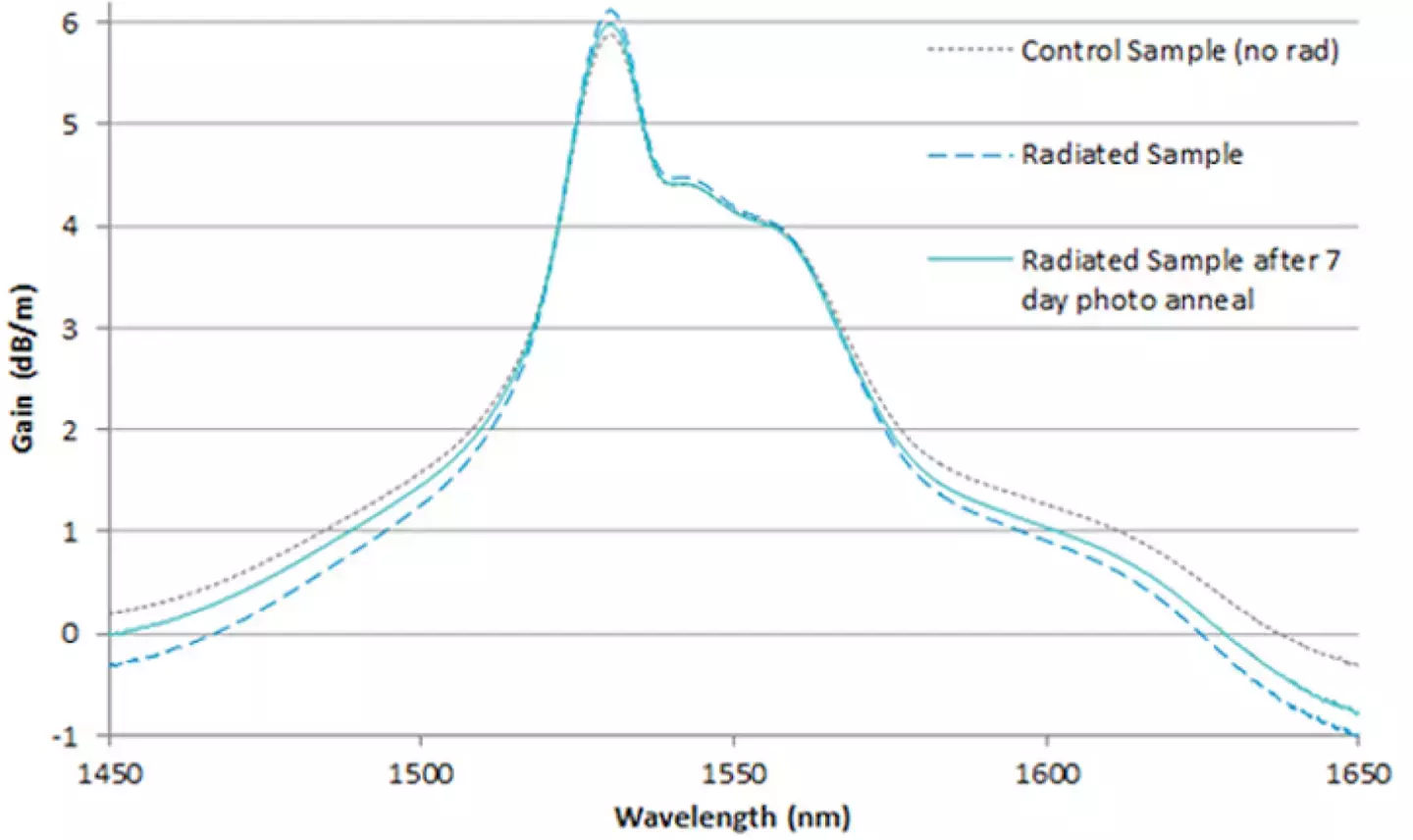

The photo-annealing effect recovers the radiation induced change in spectral gain shape of the AstroGainTM fiber. This can be seen as a considerable recovery of the post photo-anneal trace from the radiated trace in Figure 2. It is considered that pumping at specific resonant wavelengths can more effectively anneal point defects. The results from the fiber samples tested suggest the trivalent composition of AstroGainTM results in certain material defects that react favorably to pumping at 980nm.

Figure 2: AG980H fiber gain spectra before irradiation, after irradiation (200Gy) & after a 7 day (~10,000 min) photo-anneal (175mW, 974nm).

Long-Term Use

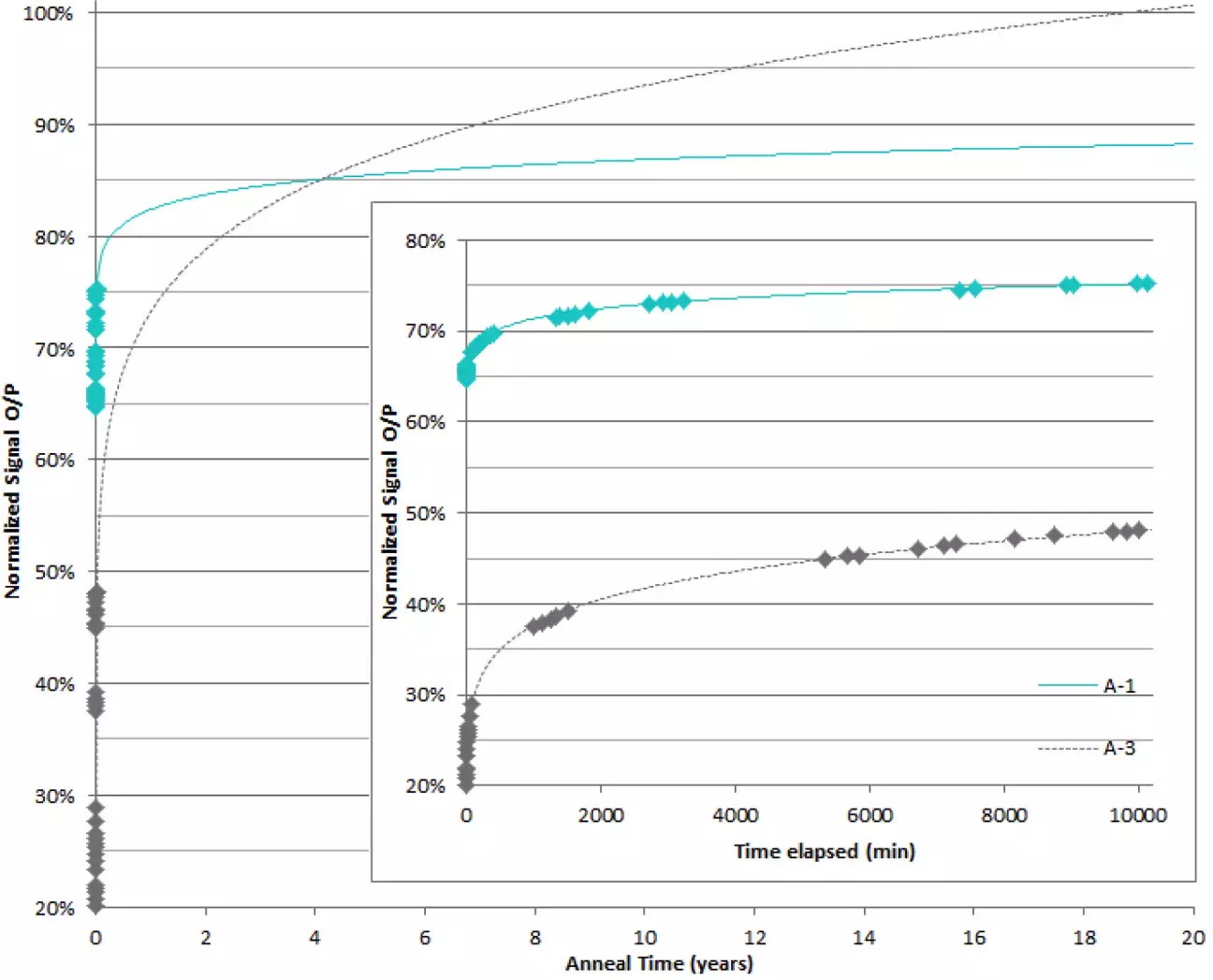

Mass budgeting is vital to any space mission due to the significant cost associated with launching any additional mass into space. The multichannel assembly used only one pump wavelength of 980nm. As can be seen in Figure 3, the results for AstroGainTM fiber AG980H suggest a full output recovery for continuous pump use over 20 years, even in this worst-case scenario. By using this specialist fiber composition, it is, therefore, unnecessary to pump additionally at 532nm. This reduces the mass that needs to be launched and gives a significant boost to power budgeting, whilst reducing the number of components in a spacecraft will intrinsically improve reliability.

Figure 3: Recovering output of AstroGainTM samples over 20 years anneal time (Inset: close up of output vs. time elapsed). A-1 = AG980L and A-3 = AG980H

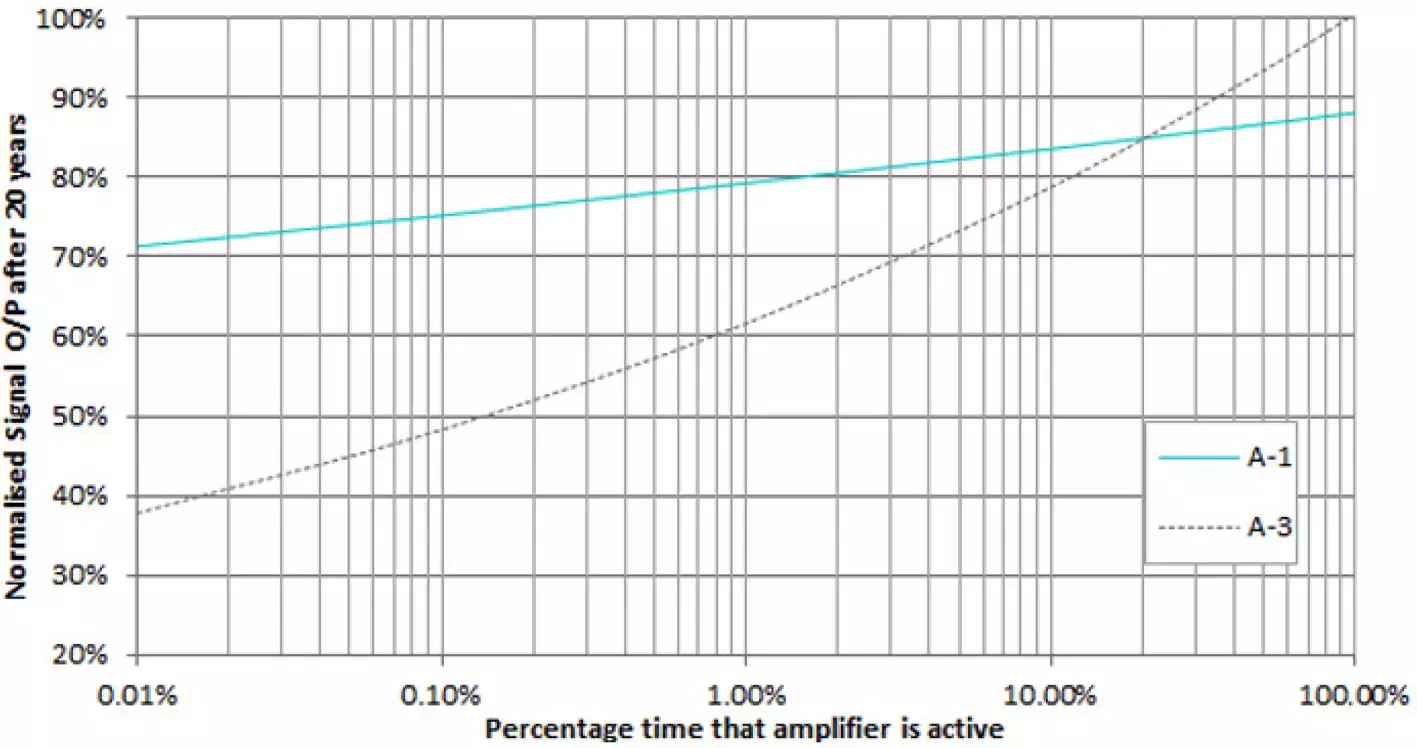

Figure 4 visually demonstrates that AG980H shows the fastest recovery even though it was damaged the most initially. The figure also recommends that if the fiber amplifier were active for greater than 20% of a 20 year mission lifetime, the best fiber to use is AG980H. If the amplifier were to be in use for less than 20% of the mission, AG980L would be the most appropriate.

Figure 4: AstroGain™ amplifier output recovery under discontinuous use.

A-1 = AG980L and A-3 = AG980H

In the case of AG980H, the result is such that Radiation-Induced Attenuation (RIA) is fully annealed and the gain spectrum is restored. This single pump annealing can be done live as part of normal operation and therefore the amplifier can remain fully functional across all channels for all of its mission lifetime.

Discover more...

Speak to our experts

Provide us with your information and our service team will contact you

Dr. Andy Gillooly

Andy Gillooly the business development manager at Fibercore (Southampton, U.K.). In 2001, Andy graduated from the University of Birmingham, with a masters degree in physics and received a PhD in fiber Bragg gratings (FBGs) from Aston University, England. He spent over four years as a senior development engineer at SPI Lasers, developing FBGs and pulsed fiber lasers. After SPI, Andy joined Sharp Laboratories of Europe, responsible for the optical design and technical customer interactions for Sharp's wafer level camera project. Later, Andy joined Fibercore where he is currently responsible for driving the company forward into new markets with new products, he has currently been with Fibercore for 14 years.