What are Fiber Optic Gyroscopes?

Fiber Optic Gyroscopes (FOGs) are high-precision sensors that measure angular velocity (rotation) using the principles of light interference in a fiber optic coil. They are widely used in navigation and guidance systems, particularly in aerospace, defense, and industrial applications where accurate motion sensing is critical.

How do Fiber Optic Gyroscopes work?

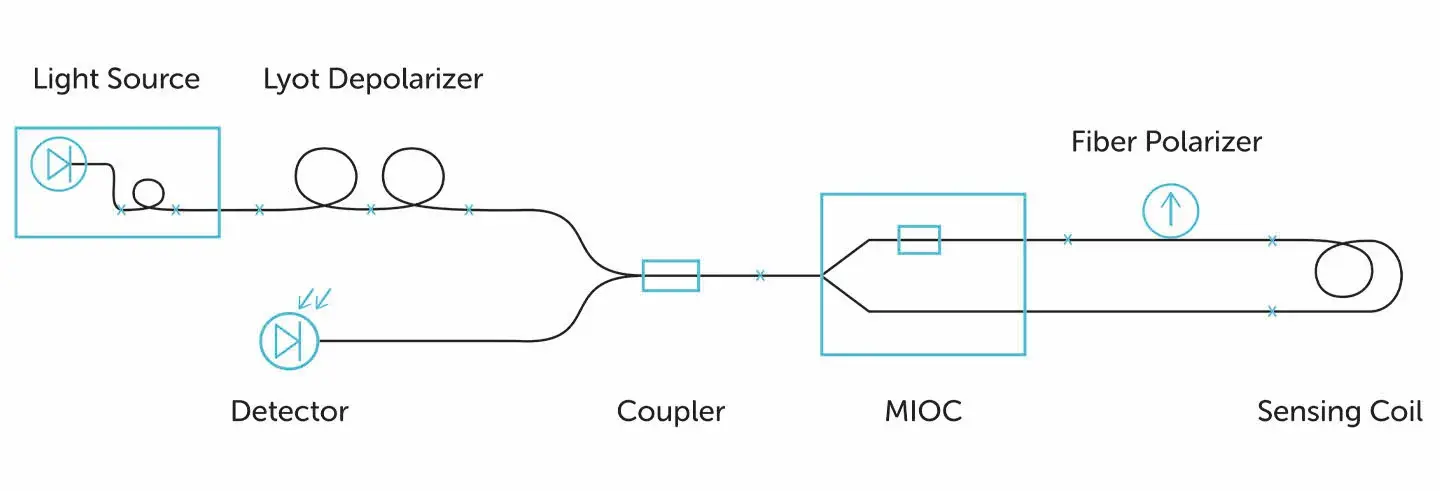

Fiber Optic Gyroscope (FOG) systems use the Sagnac effect to measure the angular velocity or rotation rate on an object (e.g. aircraft).

Two counter-propagating beams traveling through a FOG coil undergo a differential phase shift when subjected to a rotation in the plane of the coil. The magnitude of this phase shift is proportional to the rotation rate and hence it can be used to measure the angular velocity.

The FOG offers significant advantages over other IMU technology:

- Size

- Accuracy

- Low maintenance

- Long lifetime

A FOG is not sensitive to acceleration, vibration, or dithering, which means they are capable of very high signal to noise ratios (SNR), as required for the highest performance gyroscopes. They have no moving parts, which reduces the probability of mechanical failure. The technology is also scalable and can be designed into very compact volumes.

Figure 1. Design schematic of a PM FOG system.

Where are FOG's used?

Fiber Optic Gyroscopes (FOGs) provide high-precision motion sensing across various industries, enabling accurate navigation, stabilization, and positioning in demanding environments. Their reliability, durability, and resistance to electromagnetic interference make them ideal for mission-critical applications.

FOGs are extensively used in military and commercial aerospace systems, where precise motion sensing is essential for navigation, targeting, and stabilization.

- Aircraft & UAVs: FOGs enable accurate inertial navigation in GPS-denied environments, enhancing flight control and stability. In military UAVs, they help execute reconnaissance and surveillance missions with precise positioning.

- Missiles & Guided Munitions: Critical for precision targeting, FOGs provide real-time trajectory corrections, ensuring accuracy in long-range engagements.

- Submarines & Naval Systems: Used in inertial navigation systems (INS) for underwater navigation, allowing submarines to stay submerged longer as they do not have to surface to get their bearings, enabling stealthier operation without reliance on GPS.

FOGs play a crucial role in maintaining the precise orientation and stabilization of spacecraft and satellites.

- Satellite Attitude Control: Enables precise positioning to keep communication satellites aligned with ground stations, ensuring uninterrupted signal transmission.

- Deep-Space Probes & Rovers: Used for autonomous navigation of planetary exploration vehicles, compensating for long signal delays between Earth and the spacecraft.

- Space Telescopes & Optical Instruments: Helps telescopes like the Hubble Space Telescope, with high accuracy pointing in spite of movements such as vibrations that could affect observational accuracy.

FOGs support geophysical exploration and drilling operations, where accurate motion tracking is critical in challenging underground environments.

- Directional Drilling: Enables drill bits to navigate complex underground paths with precision, improving efficiency in reaching oil and gas reserves.

- Borehole Mapping & Surveying: Used in downhole measurement tools to create detailed geological maps, improving resource extraction strategies.

- Pipeline Inspection & Maintenance: Assists in robotic systems for monitoring pipeline integrity in remote locations.

Benefits of using fiber optic gyroscopes

Fiber Optic Gyroscopes (FOGs) offer several advantages over traditional mechanical, ring laser gyroscopes (RLGs), and other navigation methods like GPS-based systems. These benefits make them a preferred choice for high-precision navigation and motion sensing in demanding environments.

High Accuracy & Stability

- Minimal Drift: Unlike mechanical gyroscopes, which suffer from frictional wear, FOGs have no moving parts, leading to extremely low drift over time.

- Superior Bias Stability: Offers excellent long-term stability, making them ideal for high-precision applications like aerospace and defense navigation.

No Moving Parts = Longer Lifespan & Higher Reliability

- Reduced Wear and Tear: Unlike traditional spinning gyroscopes, FOGs rely on light traveling through optical fibers, eliminating mechanical degradation.

- Lower Maintenance: No moving components means less frequent calibration and maintenance compared to other gyroscopic systems.

Immunity to Electromagnetic Interference (EMI)

- Resistant to External Disturbances: FOGs are unaffected by magnetic fields, vibrations, or other environmental interference that can degrade the performance of mechanical or electronic gyroscopes.

- Ideal for Military & Industrial Use: Works reliably in electronic warfare environments, industrial machinery, and high-radiation settings (e.g., space applications).

Compact, Lightweight, and Scalable

- Size & Weight Advantage: FOGs are much smaller and lighter than mechanical or ring laser gyroscopes (RLGs), making them suitable for applications where size and weight are critical, such as UAVs, missiles, and satellites.

- Scalability: The technology can be adapted for different sensitivity levels by adjusting the length and properties of the optical fiber.

Fast Response Time & Wide Dynamic Range

- Instantaneous Measurements: FOGs provide real-time angular velocity readings with high bandwidth, making them highly responsive to rapid changes in motion.

- Wide Dynamic Range: Can detect both very slow and very fast rotations with precision, unlike some MEMS gyroscopes, which struggle with extreme motion speeds.

Works in GPS-Denied Environments

- No Satellite Dependency: Unlike GPS-based navigation, FOGs operate independently and provide accurate positioning in tunnels, underwater, space, and other areas where GPS signals are weak or blocked.

- Essential for Defense & Space: Critical for submarine navigation, missile guidance, and deep-space exploration, where GPS is unavailable.

What optical fiber do FOG's use?

Fibercore has developed a range of optical fibers specifically for use in FOG systems. These include an extensive range of Bow-Tie design, highly birefringent gyroscope (HB-G) fibers for use as the FOG sensor coil fiber, as well as a new range of short beat length (HBG-SB) fibers optimized for the next generation of FOG coil designs. Fibercore also offers a number of supporting products, for use in other components of the FOG system, such as ZingTM polarizing fibers (HB-Z), standard PM fiber (HB), telecoms PM fiber (HB-T) and IsoGainTM erbium doped fiber for broadband ASE source generation.

HiBi Fiber for FOG Coils

Polarization Maintaining (PM) fibers for FOG systems are generally of a reduced cladding diameter design (typically 80μm) in order to: maximize fiber length in a restricted volume and improve mechanical reliability in tight coils. In order to minimize macro and micro-bend losses within compact coils, Fibercore’s range of HiBi fibers is also of a high NA design.

The HB-G range is the current standard for PM FOG fibers. Growing demand for high accuracy gyroscopes and reduced coil volumes can also be met with Fibercore’s new range of ultra-high birefringent, short beat length range of HBG-SB fiber. Both designs utilize Fibercore’s Bow-Tie structure to create the internal birefringence and resulting PM axes of the fiber.

Fibercore also offers a range of reduced coating diameter products, to further maximize the possible fiber length within restricted coil dimensions. For example, both the HB1500G-HI and HB1500G-SB/010 products encapsulate the 80μm cladding glass within a coating package of just 155μm outer diameter. The HB1500G-SB/013 product reduces the coating package further still, with an outer coating diameter of 135μm.

Radiation Tolerant FOG Fibers

Fibercore also offers FOG fiber products that are resistant to radiation damage. Products such as HB1500G-RT and HB1500G-RT-SB are designed with a radiation-hardened core and cladding composition in order to minimize Radiation-Induced Attenuation (RIA). This makes them a great choice for the high radiation environments that are often found with space applications, such as satellite attitude control, solar panel pointing on Mars rovers, or even applications in the nuclear sector.

Subscribe for Insights!

Register to receive Fibercore's latest key updates, events and relevant industry news

straight to your inbox!

Zing™ Polarizing Fiber

Typically, a single polarization state is desired within a FOG system in order to produce a stable interference pattern of the Sagnac phase shift. Fibercore has developed a range of all-fiber Zing™ Polarizing Fibers, such as HB1550Z(11/80), which are capable of stripping energy from the fast axis, leaving only light in the slow axis. By having an all-fiber device, low insertion loss, small form factor, and high-reliability polarizers can be achieved. This is particularly important for FOG systems where low sensitivity to mechanical vibration is preferable.

Depolarizer

FOG systems also commonly use depolarizers as well as polarizers. If a light source has an uncontrolled polarization state, for example, a superluminescent diode coupled into non-PM SM fiber, then it is necessary to depolarize the light before polarizing. Otherwise, the polarization state in the SM fiber can rotate, causing power fluctuations on the output of the polarizer. By splicing two PM fibers together with the stress axis offset by 45°, a Lyot depolarizer can be created. To maximize the performance of a Lyot depolarizer, it is important to choose the correct lengths of the two pieces of PM fiber. This is non-arbitrary and depends on many factors including the birefringence of the fiber, wavelength, bandwidth, and spectral shape of the light source. Fibercore’s HB series, HB-G, and HB-T series of PM fibers are ideal for use as Lyot depolarizers.

Erbium Doped Fiber

Erbium Doped Fiber (EDF) can be used to make Amplified Spontaneous Emission (ASE) light sources capable of emitting broadband incoherent light. Using a low coherence broadband light source can considerably improve the signal to noise (SNR) ratio on a FOG system, as it acts to reduce the sensitivity to backscattered light, which would otherwise have the potential to impede the Sagnac phase shift measurement. Fibercore’s IsoGainTM range of erbium doped fibers offers a wide range of absorption rates, cladding diameters, and pump wavelengths. For high conversion efficiencies IsoGainTM fibers, such as I-4(980/125) offer the best option. For short fiber lengths and smaller packing sizes, Fibercore’s high absorption EDF range, such as I-15(980/125)HC is ideal. Fibercore also offers the I-25H(1480/125) product, a reduced 80μm cladding EDF with high NA, suitable for even the smallest high-reliability coils.

Why choose Fibercore fiber?

For fiber optic gyroscope manufacturers seeking the highest standards in precision, durability, and reliability, Fibercore's range of gyro fibers provides an unmatched combination of performance, customization, and long-term value. Whether for aerospace, defense, robotics, or industrial automation, Fibercore's advanced fibers can help elevate FOG systems, ensuring they meet the most demanding requirements in diverse and high-stakes applications.

High-Performance Fibers for Precision and Reliability

Fibercore's gyro fibers are designed to provide exceptional performance in high-precision rotation sensing. These fibers are engineered to maintain low attenuation and minimal signal loss, ensuring that FOGs deliver consistent and reliable performance across various applications, including aerospace, marine, defense, and autonomous vehicles. This high level of performance is crucial when accurate measurements are needed for mission-critical systems.

Optimized for Harsh Environments

FOGs are often used in demanding environments such as submarines, spacecraft, military vehicles, and industrial automation systems. Fibercore's gyro fibers are specifically built to withstand these harsh conditions, offering robustness against factors like temperature variations, vibrations, and electromagnetic interference. This resilience ensures that FOG systems remain operational and accurate, even under the most challenging circumstances.

Long-Term Durability

Fibercore’s fibers are designed for longevity, which is essential in applications such as spacecraft or military systems where equipment needs to endure for long periods without failure. With Fibercore's specialized fibers, manufacturers can produce FOGs that last longer with minimal degradation, ensuring that systems continue to perform reliably over time.

Innovation and Expertise

With years of experience and innovation in fiber optic technologies, Fibercore provides technical expertise that can help manufacturers integrate the best gyro fibers into their designs. Their in-depth understanding of fiber optics and its application in FOGs allows them to collaborate with manufacturers to optimize system performance, creating cutting-edge solutions for modern navigation and motion sensing applications.

Speak to our experts

Provide us with your information and our service team will contact you

Adam Saunders

Adam is the Marketing Lead for the Humanetics Sensors Group. Adam brings over 10 years of marketing experience covering campaign and strategy development, website and trade show management across B2B and B2C.