LIGHT DETECTION AND RANGING (LiDAR)

The market demand for LiDAR products has taken a steep increase as public-facing autonomous vehicles have started to be proven on the road. Whilst the autonomous vehicle market has prime focus, other applications including wind speed monitoring, range finding, and 3D scanning are more mature market areas utilizing similar, but differentiated LiDAR technologies.

Fiber-based LiDAR systems currently offer the highest optical power levels for C-band “eye-safe” wavelengths around 1550nm. Diode lasers are unable to match the power level and beam quality of a fiber laser solution in the C-band. Critically, the power level of the LiDAR light source correlates to the maximum vehicle speed for which the LiDAR system can give timely feedback. High energy pulses are able to travel further than low energy pulses before environmental scattering degrades the signal into the noise level. This allows fiber-based LiDAR systems to detect and react to events far ahead of the vehicle. Automotive applications also require high-temperature performance, capable of withstanding 125oC, which is within the performance range of various fiber coatings. Fibercore’s TC1500Y(11/125)HD erbium ytterbium doped fiber, matched passive DC1500(11/125)0.12HD fiber and GainBlocks optical engines are ideal for these needs.

LiDAR can be used to measure wind speeds at suitable stand-off distances to enable wind turbine efficiency tuning and airport safety enhancement through detection of wind sheer, wake turbulence, and gusts. Such LiDAR systems require high power, polarization maintaining, large mode area double or triple clad erbium ytterbium doped fibers.

Defense and civilian needs for range finding vary in optical power levels and the operational environments. These applications can range from ultra-high spatial accuracy length measurements of large structures, such as aircraft wings and civil engineering structures through to airborne platform targeting systems. For the lower power end, Fibercore’s IsoGain product range offers a broad selection of fibers whilst the TC range of erbium ytterbium doped fibers are suitable for the higher power ranges.

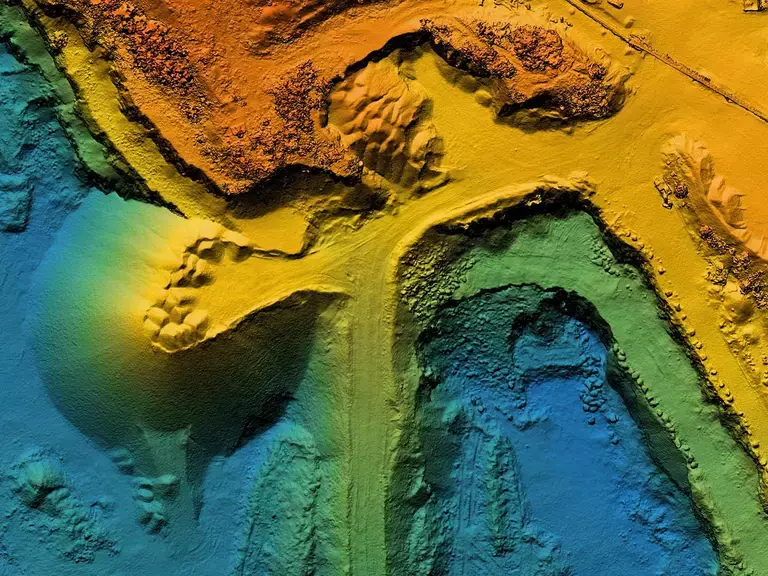

LiDAR is a powerful solution for scanning internal and external urban environments to aid construction planning and for scanning remote locations for metrological and environmental factors. The ability to mount the LiDAR systems onto mobile platforms including vehicles, boats, helicopters, aircraft, and drones enables up-to-date 3D models of an area to be constructed rapidly, ideal for low cost, large-area surveys, and emergency response situations such as floods and earthquakes.

WHY LiDAR?

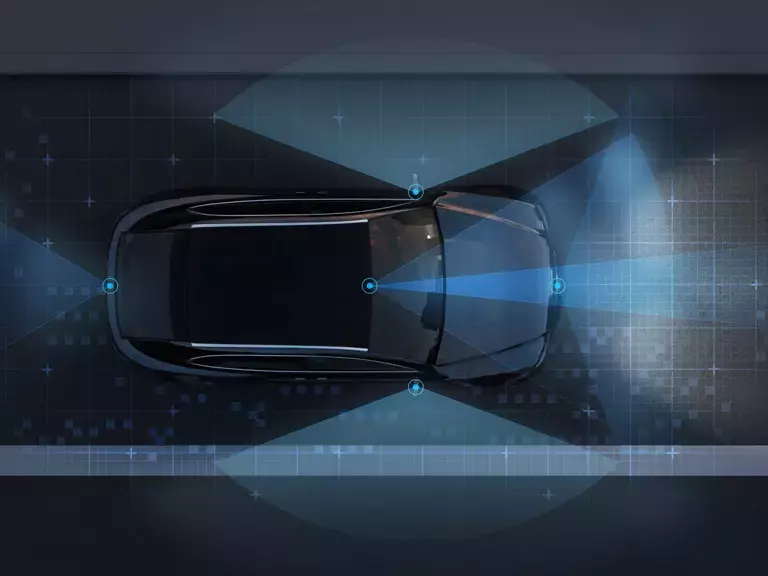

Light Detection and Ranging (LiDAR) is a remote sensing technology that uses laser beams to measure distances and create detailed 3D maps of objects and environments. It operates on the principle of emitting laser pulses and measuring the time it takes for the light to bounce back after hitting objects in its path.

The advantages of LiDAR include: high speed, precise 3D spatial data acquisition, all weather operation and long range sensing, make it a valuable tool for numerous applications in fields such as urban planning, environmental monitoring, transportation, and infrastructure management.

LiDAR technology has a wide range of applications. It is commonly used in autonomous vehicles for mapping and object detection, helping the vehicles navigate and avoid obstacles. Beyond the automotive industry, LiDAR is also utilized in wind speed monitoring for wind turbine blade angle optimization and airport operational safety, surveying and mapping architectural surroundings, environmental monitoring from airborne and space platforms, archaeology to discover undiscovered ancient towns, and many other fields where detailed 3D data is required.

WHY FIBER OPTIC LiDAR?

Fiber optic LiDAR light sources offer several benefits over other light source technologies. These advantages make fiber optic LiDAR particularly suitable for various high-performance applications.

Here are the key benefits:

High Power and Efficiency

- Power Output: Fiber lasers can produce high-power beams, which enhance the range and resolution of LiDAR systems.

- Efficiency: They convert electrical energy into light with high efficiency, leading to reduced power consumption and heat generation.

Beam Quality and Focus

- Beam Quality: Fiber lasers provide excellent beam quality with a high degree of coherence and low divergence. This results in sharper and more precise measurements.

- Focus: The narrow beam divergence enables focusing of the laser to a small spot size over long distances, improving spatial resolution.

Wavelength Flexibility

- Tunable Wavelengths: Fiber lasers can be designed to operate at various wavelengths, making them adaptable to different atmospheric conditions and target materials.

- Eye Safety: Certain wavelengths used by fiber lasers can be eye-safe, critical for applications involving human interaction.

Durability and Reliability

- Robustness: Fiber lasers are inherently robust and can withstand harsh environmental conditions, including temperature variations, vibrations, and mechanical shocks.

- Longevity: Due to having fewer moving parts, they have long operational lifetimes with minimal degradation in performance over time.

Compact and Lightweight Design

Size and Weight: Fiber optic LiDAR systems can be more compact and lightweight compared to those using other light sources. This is beneficial for applications in autonomous vehicles, drones, and portable devices.

Reduced Signal Interference

Signal Clarity: The coherence and narrow linewidth of fiber lasers reduce noise and signal interference, leading to more accurate and reliable measurements.

These benefits make fiber optic LiDAR light sources highly advantageous for advanced applications in automotive, aerospace, industrial, and environmental monitoring fields, where performance, reliability, and precision are critical.

DOWNLOAD OUR LiDAR BROCHURE

Discover the full potential of our cutting-edge LiDAR technology by downloading our comprehensive brochure. Packed with detailed product specifications, advanced features, and in-depth insights. Complete the form below to download the full brochure.

CHOOSING THE RIGHT FIBER

Fibercore’s LiDAR products are separated into different family groups based on their power handling and polarization maintaining (PM) capabilities.

For low power LiDAR or pre-amplifiers with a CW equivalent power level of <700mW, core pumped erbium doped fibers are ideal. The IsoGain range of fibers offer a broad selection of absorption levels, cut off wavelengths and fiber diameters.

- Higher absorption levels allow short fiber lengths to be used which helps suppress non-linear effects but these fibers tend to be slightly less efficient than lower absorption fibers.

- High cut off (HC) wavelength fibers provide a larger core diameter which results in higher efficiency for pump powers >300mW due to offering greater modal overlap with the pump mode.

- High Absorption Reduced Cladding (HARC) fibers are manufactured with an 80 μm cladding diameter to lower stresses when coiled tightly. They have extremely high pump absorption enabling very small package sizes to be achieved, suitable for incorporation into a QSFP style package. This enables micro-sized fiber LiDAR systems.

- The relatively flat gain spectrum makes IsoGain fibers an excellent choice for multi-wavelength or scanned wavelength LiDARs.

A PM IsoGain fiber is available for frequency modulated continuous wave (FMCW) LiDAR. This offers all of the benefits of a standard IsoGain fiber, but incorporates PANDA stress rods for quick and easy splicer recognition and accurate rotational alignment during splicing.

For higher power LiDAR systems, with signal power levels of 1W to >5W CW, the triple clad (TC) range of cladding pumped fibers are ideal. The triple clad design has been developed to enable easy handling of the optical fiber on the production line. The circular outer cladding enables standard stripping, cleaving and splicing processes to be used without the inherent variability introduced by an octagonal outer cladding. The triple clad design benefits from reducing the amount of optical power at the glass-coating interface, increasing the reliability of the optical fiber. To further aid the lifetime performance, the core has been designed with an atomic matrix which avoids photodarkening effects. These TC fibers are compatible with standard double clad (DC) fibers and subsequently require low index recoating for pump guiding splice regions.

The TC fibers are available in three variants:

- TC1500Y(6/125)HD – Optimized for 1W signal power and high efficiency conversion.

- TC1500YLP(11/125)HD – Designed for 1-4W signal power, offering a larger MFD to reduce non-linear effects in pulsed applications.

- TC1500Y(11/125)HD – Designed for ≥ 5W signal power. Above 5W this variant will display lower ASE than the LP variant.

For cost sensitive applications, lower cost, standard double clad fiber variants of the TC fibers are available, however these do not benefit from the circular outer cladding, resulting in more variable splice losses and not utilizing the improved reliability of the TC design.