Why use FBG's for Hydrophones and Geophones?

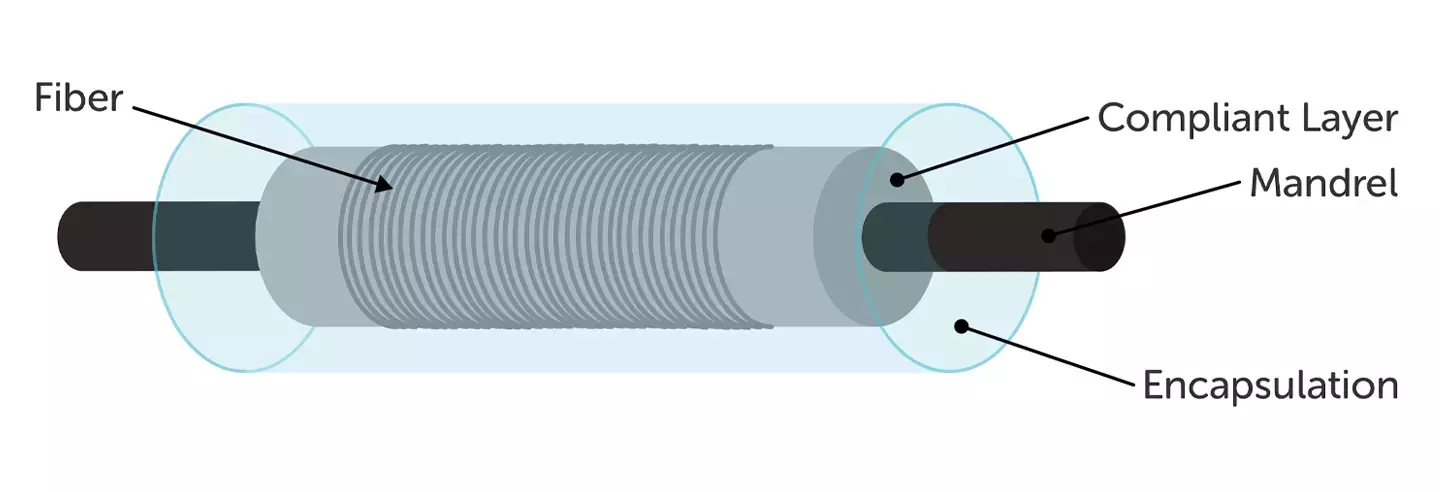

Fiber Bragg Gratings (FBGs) used in hydrophones and geophones are typically based on a highly sensitive interferometer design, optimized to be sensitive to changes in pressure caused by acoustic waves. The fiber is coiled around a mandrel (see Figure 1) which expands and contracts as a pressure wave passes across the mandrel, this in turn stretches the optical fiber coiled around the mandrel. By placing an FBG at each end of the mandrel, a Fabry-Perot interferometric cavity is created. This cavity results in a complex spectral response, which is highly sensitive to changes in the length of fiber between the FBGs. Fluctuations in the spectral response can be calibrated to the magnitude of the pressure wave and subsequently used as part of a hydrophone or geophone. By orienting three coils, with one in each of the X, Y, and Z axes, a vectorial response can be achieved to detect the direction as well as the magnitude of the acoustic wave. When combined with a Time Division Multiplexing (TDM) system, it is possible to then locate the origin and time of an acoustic event.

Figure 1. Typical fiber optic hydrophone coil design

The FBGs are typically written into 80μm bend insensitive fibers where the reduced cladding diameter gives the fiber higher mechanical reliability when coiled. An additional benefit of the reduced cladding diameter is that the fiber is more elastic than a larger cladding diameter fiber, resisting the expansion of the mandrel less and therefore giving a higher sensitivity level to the hydrophone or geophone. FBGs can also be written into 50 μm bend insensitive fibers for even greater sensitivity levels.

As geophones are often installed at great depths within boreholes, hydrogen might be prevalent, which would cause optical attenuation in standard germanosilicate photosensitive fibers. To reduce the effects of hydrogen darkening on the fiber, Fibercore offer FBGs written into non-photosensitive pure silica core fibers which do not have germanium in the core. This allows geophone systems (and other FBG sensor systems) to be installed at greater depths whilst resisting the effects of hydrogen darkening.

Speak to our experts

Provide us with your information and our service team will contact you

Dr. Andy Gillooly

Andy Gillooly the business development manager at Fibercore (Southampton, U.K.). In 2001, Andy graduated from the University of Birmingham, with a masters degree in physics and received a PhD in fiber Bragg gratings (FBGs) from Aston University, England. He spent over four years as a senior development engineer at SPI Lasers, developing FBGs and pulsed fiber lasers. After SPI, Andy joined Sharp Laboratories of Europe, responsible for the optical design and technical customer interactions for Sharp's wafer level camera project. Later, Andy joined Fibercore where he is currently responsible for driving the company forward into new markets with new products, he has currently been with Fibercore for 14 years.