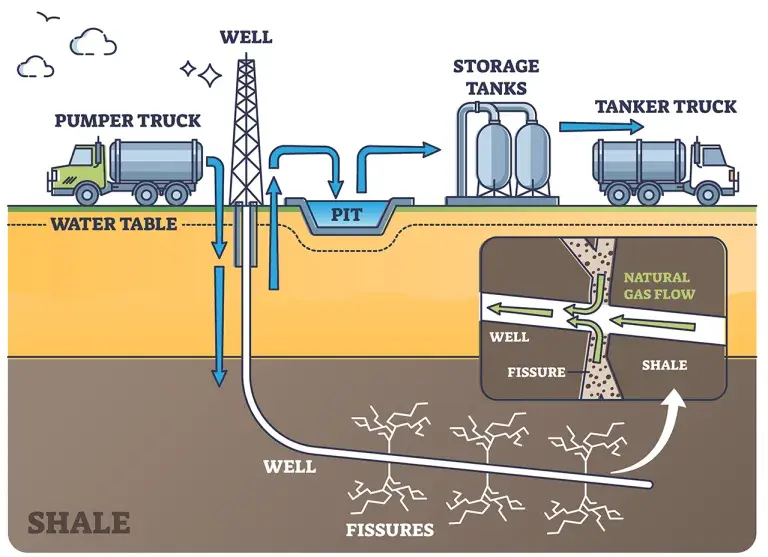

The subsurface environment of oil and gas wells presents extreme challenges—elevated temperatures, high pressures, corrosive fluids, and complex geomechanics. Conventional sensors often suffer from reliability issues or require frequent replacements. Fiber optic technology offers a robust, passive alternative that survives these harsh conditions for decades.

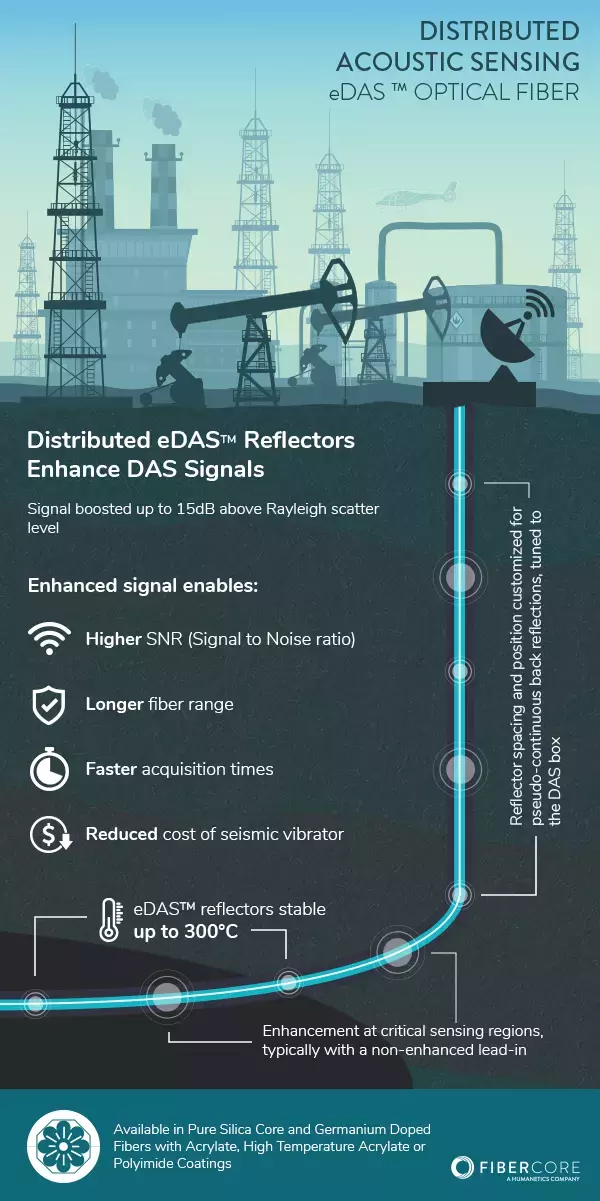

By embedding fiber optic cables within wellbores, operators gain real-time, distributed data over the entire depth of the well. Techniques like distributed acoustic sensing (DAS), distributed temperature sensing (DTS), and distributed strain sensing (DSS) unlock a 3D, time-lapse view of well activity—reshaping the future of downhole sensing and well monitoring.

WHAT IS DISTRIBUTED FIBER OPTIC SENSING?

Distributed fiber optic sensing (DFOS) leverages the scattering of light within an optical fiber to monitor physical changes along its length. It relies primarily on three types of backscattering phenomena:

- Rayleigh scattering (used in DAS) – sensitive to micro-vibrations and pressure-induced changes in refractive index.

- Raman scattering (used in DTS) – sensitive to temperature-induced phonon interactions.

- Brillouin scattering (used in DSS and DTS) – responsive to both strain and temperature through frequency shift analysis.

A single-mode optical fiber, when interrogated by a laser pulse, returns these scattering signatures, which are interpreted to localize and quantify changes along the fiber. This turns the fiber into a continuous sensor, unlike point-based electrical sensors.

Key technical advantages:

- Spatial resolution: Down to <1 meter.

- Temporal resolution: Sub-second to real-time.

- Sensing range: Up to 50 km per channel, extendable via multiplexing.

APPLICATIONS IN OIL AND GAS

Distributed acoustic sensing (DAS) is capable of detecting microseismic events and fluid movement by capturing pressure waves across the fiber. This enables fracture mapping and stimulation effectiveness analysis in real time. Combined with DTS, which records thermal cooling effects during fluid injection, operators can identify active fracture zones, optimize cluster spacing, and minimize treatment overlap.

Example: In horizontal shale wells, DAS can track perforation shots and fluid arrival times across multiple stages, improving completion design and reducing non-productive time (NPT).

Leaks in casing, tubing, or completion hardware often cause temperature and pressure anomalies. DTS systems detect these with high sensitivity (as little as 0.01°C) and can pinpoint their exact location along a wellbore. When combined with DAS, operators also hear acoustic cues like bubbling or high-frequency turbulence.

Advanced flow profiling is achieved by analyzing DTS response to fluid movement during production or injection. In intelligent completions, this data can be correlated with zonal isolation and inflow control valve (ICV) settings for optimized production.

Distributed Fiber Optic Sensing technology measuring strain sensitive phase changes in the scattering profile captures micro-deformations in the casing or formation. This is critical for:

- Cement bond evaluation

- Sand production monitoring

- Geomechanical modeling

- Fault slip and compaction detection

Early detection of strain anomalies allows for proactive remediation, reducing the risk of catastrophic casing collapse or zonal communication

In thermal EOR methods like SAGD, DTS plays a pivotal role in ensuring steam placement efficiency. Temperature profiles across producer and injector wells guide conformance control and steam optimization. Fiber optic sensors can also withstand cyclic steaming conditions, delivering reliable feedback for decades.

Additionally, DAS can detect steam flashing and channeling effects, helping operators adjust injection strategies dynamically.

Advantages of Fiber Optic Sensing in Harsh Environments

High Temperature Tolerance

Fibers coated with polyimide withstand >300°C, ideal for geothermal or HPHT wells.

Pressure Resistance

Encapsulation techniques (e.g., metal tube, glass-to-metal seal) maintain integrity under pressures exceeding 25,000 psi.

EMI Immunity

Optical signals are unaffected by electromagnetic interference—critical for offshore and deepwater applications.

No Active Downhole Components

No electronics or power source are required in the well—only passive fiber and a surface interrogator.

Multiplexing Capability

Multiple sensing fibers or zones can be interrogated through a single fiber or using wavelength division multiplexing (WDM).

Subscribe for Insights!

Register to receive Fibercore's latest key updates, events and relevant industry news

straight to your inbox!

FIBERCORE’S ROLE: HIGH-PERFORMANCE FIBER SOLUTIONS

Fibercore specializes in custom-designed fibers that meet the mechanical, optical, and chemical performance demands of the energy industry. Our offerings include:

- Hydrogen-Resistant Coatings: Such as carbon or hermetic layers to mitigate hydrogen darkening in wet completions.

- Hydrogen-Resistant Glass Chemistries: For use in key wavelengths employed by various DFOS technologies.

- High Reliability: Long life

- Specialty Single-Mode Fibers: Engineered for high-sensitivity DAS and stable Brillouin response in DSS.

- Radiation-Hardened Fibers: With doped core compositions to resist gamma-induced attenuation.

Our fibers are trusted by leading service companies and downhole tool manufacturers for performance-critical distributed sensing deployments worldwide.

The Future of Subsurface Monitoring

As wells become deeper, hotter, and more complex, fiber optic sensing provides the scalability, precision, and durability needed for modern field development. Whether enabling smarter completions, improving recovery, or ensuring safety, distributed fiber optic sensing is shaping the intelligent oilfield of tomorrow.

READ MORE

Explore more of our expert insights—click below to discover related articles that dive into fiber optic technologies and their real-world applications.

Speak to our experts

Provide us with your information and our service team will contact you

Adam Saunders

Adam is the Marketing Lead for the Humanetics Sensors Group. Adam brings over 10 years of marketing experience covering campaign and strategy development, website and trade show management across B2B and B2C.